So much has changed over the last 50 years, but pill bottle packaging has stayed the same.

We found ourselves thinking that there has to be a way to improve the pill taking experience, one that makes it easy to follow dosing schedules.

The last significant change to pill bottles was the introduction of child resistant caps in 1973. Since then, companies have relied exclusively on this design for their bottle packaging needs. This lack of innovation has caused problems and created a significant opportunity to improve the consumer’s pill taking experience.

As with everyone accustomed to the status quo, we never gave much thought to pill bottles. We assumed that if there was something more that could be done the bottle manufacturers would have already done it. And yet, like other consumers, we often found ourselves forgetting whether we’d taken our pills and then wondering if it was better to risk taking a second dose than missing one. This got us thinking and led us to take a closer look at the issue.

Our research led us to question the wisdom of the current pill bottle design.

Why is medication adherence arbitrarily defined as taking 80% or more (instead of 100%) of scheduled doses?

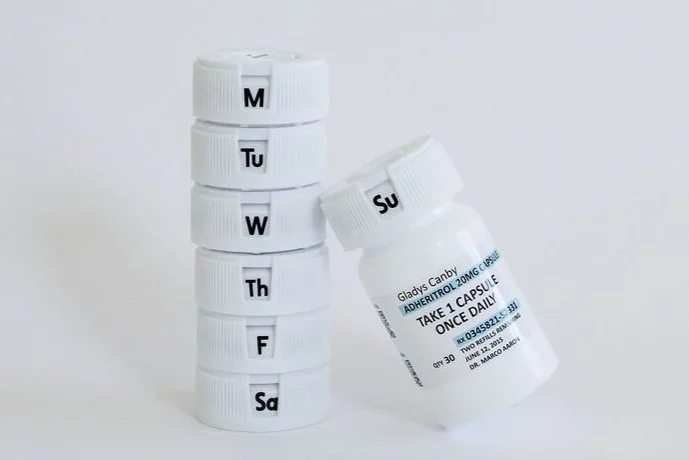

What’s the point of child resistant packaging if consumers are removing medications from the original packaging and putting them in pill boxes or on the counter so they can remember to take them later?

Why do pharmaceutical companies spend millions ensuring that participants in their drug trials take every scheduled dose, while at the same time packaging their approved drugs in bottles that don’t set consumers up for success?

Are the aftermarket products and interventions designed to help consumers follow dosing schedules a symptom of the shortcomings of the current pill bottle design?

While there are many reasons consumers aren’t adherent, and forgetfulness is at, or close to, the bottom of this list, why aren’t pharmaceutical and pharmacy companies more committed to improving their adherent consumers’ pill-taking experience? (This puzzled us, as this population accounts for more than 80% of their revenues, wants to take every dose, and even a small increase in their consumption represents billions in additional sales.)

Nothing about this pill bottle space made sense to us. Everywhere we looked we saw problems and an enormous opportunity to address them with a new pill bottle design. And because we like a challenge as much as the next guy, we began our quest to reinvent the pill bottle by identifying things that wouldn’t work. This led us to eliminate electronics (too expensive and complicated), everything requiring consumers to do something they aren’t already doing, and every solution that wasn’t simple, low cost, and scalable. We then turned our attention to what consumers are doing (removing and replacing the cap each time they take their scheduled dose) and asked ourselves if we could modify the bottle cap so that each time the consumer takes their pills an indicating ring automatically advances to the time of the next scheduled dose. The result is RedCap, a cap that’s compatible with industry standard pill bottles and can be used by companies in their packaging to delight consumers by empowering them to take their medication reliably and safely - every day and at every dose.

We’re Massachusetts based and partner with Fikst Product Development (a Re:Build Manufacturing Company), F&M Tool & Die, Roehr Tool Solutions and Sterling Manufacturing to design and manufacture RedCaps.